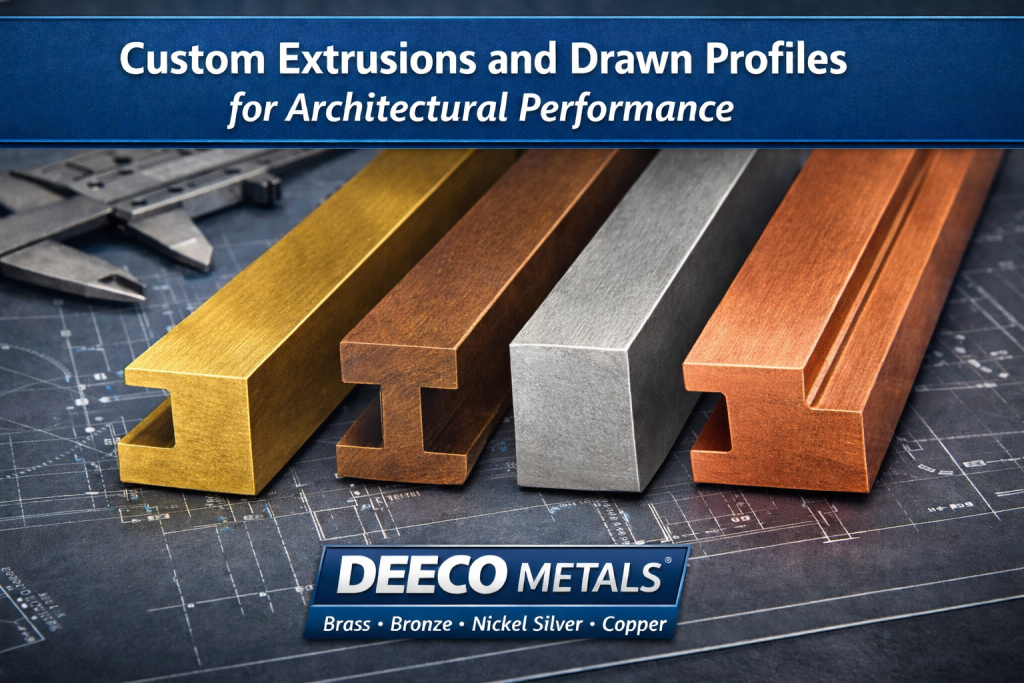

Where reliable engineering meets elevated design.

Architects and manufacturing engineers depend on materials that perform consistently, look refined, and support long-term use in demanding environments. Brass, bronze, copper, and nickel silver remain some of the most effective choices for profiles that must combine mechanical strength, clean appearance, and dimensional accuracy. When engineered correctly, these alloys deliver the reliability that modern architectural systems require.

DEECO Metals supplies custom extruded shapes in brass, bronze, copper, and nickel silver, along with drawn brass profiles for projects where quality, precision, and timely responsiveness are essential.

Why Brass, Bronze, Nickel Silver and Copper Shapes Work Well in Architectural Systems

These metals offer a balance of strength, corrosion resistance, and formability that is difficult to match. They provide warm, refined finishes that withstand continuous contact, moisture, and heavy use. The alloys handle complex geometries cleanly, are highly machinable, and support premium finishing processes that enable designers to achieve both functional and aesthetic goals.

Customers rely on these materials because they deliver:

• Long-term durability in interior and exterior environments

• Attractive surface finishes suited for premium spaces

• Excellent corrosion resistance for doors, entries, and public areas

• Natural antimicrobial performance for high-touch zones

• Predictable forming, fabrication, and machining results

• Dependable performance when profiles require tight tolerances

These qualities make brass, bronze, copper, and nickel silver a dependable choice for projects where both beauty and function matter.

Custom Brass, Bronze, Nickel Silver and Copper Extrusions Built for Architectural Demands

Extruded copper alloy profiles form the backbone of many architectural features. DEECO engineers each shape to meet exact specifications, ensuring that every detail performs as intended once installed.

• Decorative trims and mouldings

• Sills, thresholds, and specialty transition pieces

• Door and window framing components

• Glazing channels and structural support profiles

• Handrail systems and balustrade elements

• Custom shapes for luxury interiors or branded environments

Each extrusion is produced with consistent straightness, controlled dimensions, and a surface quality suitable for sanding, brushing, polishing, or patina finishes. This reduces fabrication time while maintaining a high-level presentation.

Drawn Brass, Bronze, Nickel Silver and Copper Shapes for Projects Requiring Precision

When an application demands tighter control, drawn brass shapes provide the enhanced performance needed to meet demanding tolerances. The drawing process increases mechanical strength, improves surface uniformity, and sharpens dimensional accuracy.

Customers select drawn shapes when they need:

• Precision fit in assemblies and hardware

• Superior straightness and dimensional stability

• Higher tensile strength for high-use components

• Uniform surfaces for visible trim or finishing

• Repeatability across low to high-volume programs

These profiles are commonly used in locking systems, sliding tracks, glazing beads, specialty channels, and mechanical features that require smooth and reliable operation.

Matching the Right Brass, Bronze, Nickel Silver, and Copper Alloy to the Job

The correct alloy selection ensures long service life and consistent performance. DEECO guides customers toward the best option based on environment, appearance, and fabrication needs.

Architectural projects often use:

• C360 free machining brass for profiles requiring extensive machining

• C380 and C385 architectural brass and bronze for decorative elements

• C110 ETP copper for electrical conductivity & green or copper-colored accents achieved through acid etching & various patinas

• Manganese and naval brasses or bronzes for harsh environments and higher strength requirements

Each alloy brings a specific advantage, and our engineering team helps customers meet both performance and cosmetic objectives.

Why Leading Architectural and OEM Teams Work with DEECO Metals

Customers rely on DEECO Metals because we focus on making their job easier. We combine metallurgy, engineering, global sourcing, and manufacturing experience to produce brass, bronze, copper, and nickel silver shapes that arrive ready for real-world demands.

• Custom dies engineered for complex architectural profiles

• Controlled extrusion, roll forming, and straightening processes

• Precision die drawing for close dimensional tolerances

• High-quality surface preparation and finishing support

• Strict dimensional and quality inspection

• Long-term supply programs and JIT inventory solutions

• Reliable lead times through trusted global partnerships

Profiles must install cleanly, operate smoothly, and maintain their appearance for years. Consistency is essential.

Bringing Performance and Design Together

Modern architecture continues to push for materials that elevate appearance while supporting long-term durability. Brass, bronze, copper, and nickel silver deliver on both fronts, and when shaped through advanced extrusion and drawing processes, they become some of the most dependable components in any project.

DEECO Metals supplies profiles engineered with your performance, timeline, and design goals in mind. From low to high-volume OEM programs to signature architectural features, we provide reliable metal solutions that support quality buildings and lasting results.

Looking for a reliable source for custom brass, bronze, copper, or nickel silver shapes?

Request a quote from DEECO Metals. Speak directly with our engineering team via email sales@deecometals.com, visit www.deecometals.com or call 1-800-BRASS-84.